Embedded NVM

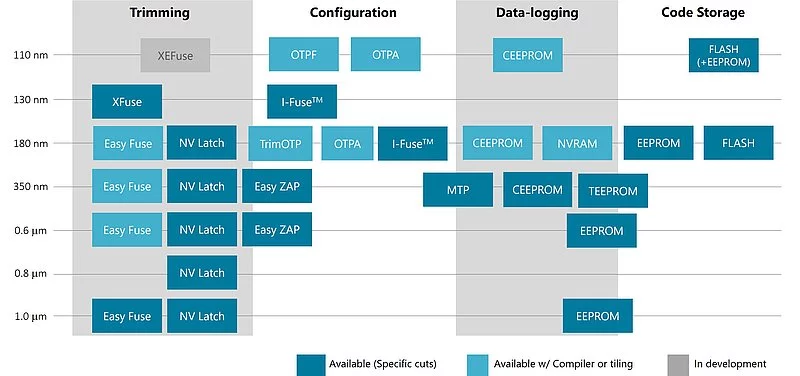

Each of our technology platforms comes with a broad offering of proven, embedded non-volatile memory (e-NVM) solutions that support all possible customer applications.

Best-in-class reliability

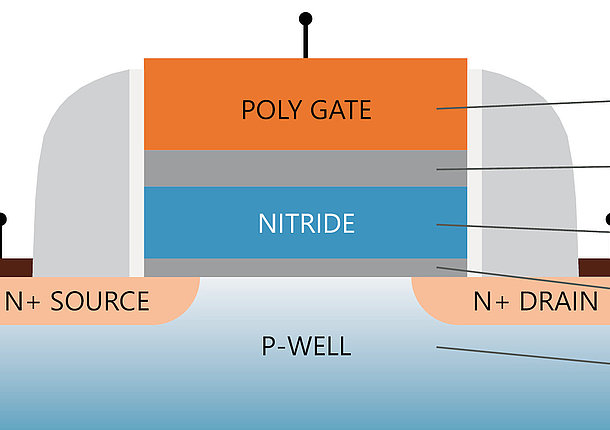

Most of our e-NVM offering is qualified and proven in the field according to the most stringent automotive standards. Compared to other solutions on the market, it provides best-in-class resiliency and zero-defect operation even under the most demanding conditions. We have achieved this feat by selecting the most appropriate technologies, like SONOS flash, and mastering the whole design-to-manufacturing process, in particular to serve the automotive market.

Facilitating customer’s product management

As the proprietor of both the technology platforms and the e-NVM IP design, we are in the right position to develop e-NVM solutions that either minimize or completely eliminate the need for additional process layers to the core module. This enables our customers to benefit from extensive IP reuse across different product families, helping to optimize product portfolio and roadmap management.

Design flexibility

The availability of flexible memory cut selection, through compilers or sliceable elementary cells, enables our customers to smoothly pick and accommodate the most suitable e-NVM solution for their design, optimizing footprint and die cost. The required design documentation is made available in real time and is compatible with all major EDA tools, making the process of embedding the IP into the customer’s product a seamless, plug-and-play task.

One-stop shop

Our full in-house expertise of the NVM development process, which encompasses memory design, qualification, testing and continuous customer support, allows us to offer joint development of customer-specific solutions when required.

FeatureXplorer – Your access to our e-NVM portfolio

More information and details about our e-NVM portfolio can be found in the FeatureXplorer, where you can select the right foundry process for your next chip design.

Applications

Solutions

Circuit trimming, configuration and traceability

Customizable, one-time-programmable (OTP) memory:

Available in the following technologies: XO035, XH035, XC018, XH018, XP018, XT018, XS018, AH018, XR013

Target application domains:

- Automotive (specifically intended), medical, industrial, computers/communication/consumer (CCC)

Typical system applications:

- Analog circuit trimming

Physical mechanism:

- Polysilicon fuse

Key features:

- Automotive AEC100-0 qualified, read temperature up to 175°C

- Flexible cut design (slice-able tiles) from 2 to 128 bit

- No additional masks/layers required on core process

Compiler-based OTP memory:

Target application domains:

- Automotive (specifically intended), medical, industrial, CCC

Typical system applications:

- Circuit trimming

- System configuration

- Basic code storage

- Product debugging

Physical mechanism:

- Floating gate

Key features:

- Automotive AEC100-0 qualified, read temperature up to 175°C

- Compiler-based, flexible cut design, from 8 bit up to 16 Kbit

- No additional masks/layers required on core process

- UV-erasable, rewriting option

Customizable, OTP memory:

- Available in the following technologies: XDH10, XDM10, CX08, CX06, XC06, XB06, XT06, XA035, XH035, XO035

Target application domains:

- Automotive, medical, industrial, CCC

Typical system applications:

- Analog sensor trimming

- MEMS sensor signal trimming

Key features:

- No additional masks/layers required on core process

- Flexible cut design (sliceable cells)

OTP memory IP:

- Specifically designed for the following technology: XR013

Target application domains:

- Radio frequency (RF) consumer, industrial Internet of Things (IoT)

Typical system applications:

- RF analog trimming and configuration

Key features:

- No additional masks/layers required on core process

- 2 Kbit cut available (other cuts on demand)

- Industrial grade

Core-EE latches – customizable, multi-time-programmable memory latches:

Target application domains:

- Automotive, medical, industrial, CCC

Typical system applications:

- Analog sensor trimming

- MEMS sensor signal trimming

- Product configuration debugging

Key features:

- Automotive AEC100-1 qualified, read temperature up to 140°C

- No additional masks/layers required on core process

- Flexible cut design (slice-able cells)

Customizable, multi-time -programmable memory latches:

Target application domains:

- Automotive, medical, industrial, CCC

Typical system applications:

- Analog sensor trimming

- MEMS sensor signal trimming

- Product configuration debugging

Key features:

- Flexible cut design (sliceable cells)

Data storage and data logging

Compiler-based Core-EEPROM, with zero mask adders:

Target application domains:

- Automotive (specifically intended), medical, industrial, CCC

Typical system applications:

- Sensor and MEMS system configuration

- Security, diagnostics and traceability data logging

- In-the-field sensor data logging

- Improved flexibility for code storage update

Physical mechanism:

- Floating gate

Key features:

Tiny-EEPROM solutions, available in different cuts:

Target application domains:

- Automotive, medical, industrial, CCC

Typical system applications:

- Automotive and IoT sensor system configuration and code storage

- Companion chip configuration for MEMS-based applications

- In-the-field sensor data logging

Physical mechanism:

- Floating gate

Key features:

- Automotive AEC100-0 qualified, read temperature up to 175°C

- 100,000 storage cycles

- Large availability of different cuts for all customer needs

SONOS- based EEPROM:

Target application domains:

- Automotive (specifically intended), medical, industrial, CCC

Typical system applications:

- Sensor and MEMS system configuration

- Security, diagnostics and traceability data logging

- In-the-field sensor data logging

- Improved flexibility for code storage update

Physical mechanism:

- Oxide-nitride charge trapping

Key features:

- Automotive AEC100-0 qualified, operation temperature up to 175°C

- 100,000 program cycles

Compiler-based NVRAM. (SRAM + SONOS-EEPROM)

- Available in the following technology: XH018

Target application domains:

- Automotive, medical, industrial, CCC

Typical system applications:

- Low-power and portable sensor applications

- Brown-out data protection and recovery

- Data access speed optimization

Physical mechanism:

- SRAM + SONOS-based EEPROM (oxide-nitride charge trapping)

Key features:

- Automotive AEC100-0 qualified, full operation temperature up to 175°C (read, write, store to EEPROM)

- Unlimited program cycles to SRAM, 100,000 storage cycles

- Compiler-based flexibility for size and form factor

- No additional masks required to the core process

Code storage

Embedded flash cut based on SONOS proprietary technology

Target application domains:

- Automotive, medical, industrial, CCC

Typical system applications:

- Resilient code storage for CPU applications

- Proven with proprietary, RISC-V and ARM® applications

- Edge sensor configuration and operation

- System bus interface with edge nodes

- Advanced computational power for MEMS applications

Physical mechanism:

- SONOS-based (oxide-nitride charge trapping)

Key features:

- Available in 16 kB and 32 kB cut

- Best-in-class reliability specifications: AEC100-0 qualified,operation temperature up to 175°C

- Embedding error code correction (ECC) for zero-defect approach

- Optimized footprint

- Specific test interface provided, full test services available on demand

Embedded flash with EEPROM included, both based on SONOS proprietary technology:

- Available in the following technology: XT018

Target application domains:

- Automotive, medical, industrial, CCC

Typical system applications:

- Resilient code storage for CPU applications

- Systems requiring frequent code upgrades or self-adapting to environment change

- Edge sensors configuration and operation

- System businterface with edge nodes

- Advanced computational power for MEMS applications

Physical mechanism:

- SONOS based (oxide-nitride charge trapping)

Key features:

- Available in two configurations: 32 kB and 64 kB

- Competitive footprint solution: flash and EEPROM sharing the same circuitry, while keeping independent operation

- Best-in-class reliability specifications: AEC100-0 qualified, operation temperature up to 175°C

- Designed to be compatible with ECC, for zero-defect approach

- Optimized footprint

- Specific test interface provided, full test services available on demand

Related Resources

Contact

Nando Basile

Technical Marketing Manager

e-NVM

For more information, please contact us: